эво 10 |

Здравствуйте, гость ( Вход | Регистрация )

|

эво 10 |

15.12.2008, 16:49 15.12.2008, 16:49

Сообщение

#1

|

|

Зарегистрированный пользователь  Группа: Пользователи Сообщений: 504 Регистрация: 19.11.2007 Из: мичуринск |

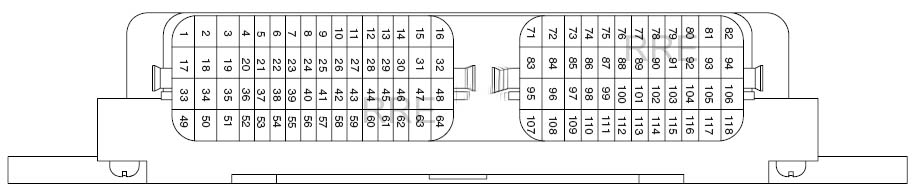

помогите с распиновкой блока

|

|

|

|

15.12.2008, 18:29 15.12.2008, 18:29

Сообщение

#2

|

|

Зарегистрированный пользователь  Группа: Пользователь Сообщений: 1715 Регистрация: 22.6.2006 |

|

|

|

|

15.12.2008, 18:31 15.12.2008, 18:31

Сообщение

#3

|

|

Зарегистрированный пользователь  Группа: Пользователь Сообщений: 1715 Регистрация: 22.6.2006 |

|

|

|

|

15.12.2008, 19:35 15.12.2008, 19:35

Сообщение

#4

|

|

Зарегистрированный пользователь  Группа: Пользователи Сообщений: 504 Регистрация: 19.11.2007 Из: мичуринск |

спасибо

|

|

|

|

28.1.2009, 13:00 28.1.2009, 13:00

Сообщение

#5

|

|

Зарегистрированный пользователь  Группа: Пользователь Сообщений: 1715 Регистрация: 22.6.2006 |

роман 68

тоже задумался надо установкой шифт-лайта. а где у десятки RPM-signal? |

|

|

|

| Гость_Тигр_* |

28.1.2009, 13:45 28.1.2009, 13:45

Сообщение

#6

|

|

Гости |

Парни, зачем вам это? Объясните плиз.........очень интересно!

|

|

|

|

28.1.2009, 14:33 28.1.2009, 14:33

Сообщение

#7

|

|

Зарегистрированный пользователь  Группа: Пользователь Сообщений: 1715 Регистрация: 22.6.2006 |

Цитата(Тигр) Парни, зачем вам это? Объясните плиз.........очень интересно!

http://www.tuningevo.club/forum/viewtopic.php?p=182368#182368 |

|

|

|

| Гость_Тигр_* |

28.1.2009, 14:45 28.1.2009, 14:45

Сообщение

#8

|

|

Гости |

Boba

Понял! Пасиб! |

|

|

|

26.4.2009, 10:14 26.4.2009, 10:14

Сообщение

#9

|

|

Зарегистрированный пользователь  Группа: Пользователь Сообщений: 1715 Регистрация: 22.6.2006 |

omei Technical Report - Garage.Tech

Bigger Valves And Plugs With Decreased Diameter Upon measuring the cylinder valves, the 4B11 consists of 35mm intake and 29mm exhaust valves. The 5.5mm valve stems reveal that the new valves are definitely larger than that from the 4G63. with these increased factors, the spark plug size was decreased to optimize valve seat and spark plug hole clearance. Compared to an sR unit with the same bore, the intake is shown to be bigger by 1mm, while the exhaust valve is smaller by 1mm. Exhaust Valve Designed With The Environment In Mind The exhaust camshaft was found to have less lift and angle than the previous 4G63 model. The objective of the 4B11 camshaft was designed to produce a cleaner exhaust gas while exhibiting good power output with the help of MIvEC. The sodium-filled valves found in the 4G63 have now been replaced with standard surface-treated units, which were considered for environmental reasons. Tomei Powered engineers have reason to believe a drawback with the 4B11 exhaust valves may be prone to heat damage since the seat rings and valve guides weren't manufactured with copper materials. Camshafts With No Rocker ARMS The rocker arm setup was tossed aside for a direct acting configuration. This new setup means that there are less moving components needed for operation, allowing for a compact design with less mechanical trouble and friction, which the camshaft lobes benefit from the most. The camshaft specs measured in at 254-degrees intake with 9.4mm lift and 224-degrees exhaust with 8.2mm lift. valve lifters, which were measured at 35mm diameter and 23.9mm height, were combined with shims that allow valve clearance adjustments also found on the new 4B11 engine. For those who consider altering this area in the near future, Tomei engineers have found the lift can be raised 2mm and the valvesprings and lifter nose should clear-if the base circle has been kept standard. Lightweight Valvesprings The lifters, retainers and valves were noticeably different in design compared to previous engine models with the focus of lightweight engineering in mind. Tomei engineers found that the valves have plenty of room from bottoming out but the 4B11 spring rates are rated fairly low. Therefore, in terms of tuning aspects, these might need to be replaced to a stiffer aftermarket set depending on the camshaft profile and lift. Mivec On Intake And Exhaust The 4B11 was engineered with clean, environmentally friendly emissions while delivering a significant amount of power. The MIVEC feature (4B11 engine uses MIVEC on both intake and exhaust variable valve timing systems) is mainly responsible for this great balance of two opposite features. Even though the Evo Ix 4G63 was equipped with the variable valve timing on the intake side only, the 4B11 proves to have added improvements on low to midrange torque. The MIVEC is controlled with an ordinary vein that partitions two different chambers managed with two different pressures. 4G63 Timing Belt Replaced With Silent Chain A silent chain instead of the traditional timing belt powers the 4B11. Chains are beneficial over belts due to the lack of friction loss and increased longevity. The front timing cover consists of a single unit not split into upper and lower sections, which create a problem when servicing or performing modifications such as head/block resurfacing or a headgasket change. Tomei engineers found that compression changes can be more troublesome when altering the 4B11 engine. Metal Headgasket The headgasket is measured at 0.9mm thick and consists of a five-layer laminated-metal type. due to the laminated headgasket design, proper head seating issues may occur after modifying the engine. Stretch-Type Head Bolt Angle Tightening Method (Torque To Yield Torque Procedure) The torque to yield method used elastic stretch-type bolts to tighten the 1mm length head bolts. since the engine has an aluminum block, the bolts are longer with increased torque specs. The washers on the bolts are fixed except for No. 1 for the ease of service and maintenance. Evo X 4b11 Engine Analysis: Part 2 The newly introduced 4B11 DOHC 16V turbo MIVEC engine is the latest talk of the town as engineers and performance tuners have lined up to get their hands on the new powerplant in hopes of unlocking the hidden mysteries that have shrouded the Mitsubishi powerplant. When we left off, the Tomei Powered engineers had gone into extensive details on the 4B11 T/C upper cylinder head. As we continue our second and final analysis, we should point out that the 4B11 found in the milder version Mitsubishi Lancer rated at 152 hp and 146 lb-ft of torque, while the 4B11 T/C inline-four turbo found within the Lancer Evolution and '08 Lancer Ralliart sold in North America delivers a factory rating of 295 hp and 300 lb-ft of torque. Both engines sport the same 2.0-liter displacement but were designed and built by Mitsubishi engineers to handle two completely different power levels. The 4B11 T/C was designed by Mitsubishi with a lower compression ratio (9:1) to handle boost and consists of numerous reinforcements to withstand a higher generated horsepower. The most significant change from the 4G63 engine to the new 4B11T was the change in material used in the block design. The 4B11 block, the first engine in the Lancer Evolution series that uses a die-cast aluminum cylinder block, is comprised of a lighter aluminum construction, which is considered a huge change compared to the previous cast-iron 4G63. Mitsubishi managed to save 27 pounds using the lighter aluminum from its previous cast-iron setup. But has the cost of shedding a few pounds and a new block design jeopardized the legendary Mitsubishi Lancers reputation for a nearly bulletproof bottom end? Before you jump to any conclusions, read on as Tomei Powered completes their analysis of the 4B11. Four-Bolt Crank Cap Increases Block Strength For each journal, four bolts clamp down each of the crank caps to increase the block strength and rigidity. This design is widely seen in V-style engines and not much so in inline or straight-style engines. Four bolts provide more strength than the conventional two-bolt style and is a step in the right direction for Mitsubishi engineers. Cylinder Block That Endures High-Power Output The newly engineered aluminum die-cast block features a half-skirt design, which was incorporated to decrease the overall length of the engine. The bore pitch measured in at 96mm compared to the popular SR- 20DET engine that measures 97mm. The crank caps are equipped with four bolts and the two-structure ribbed oil pan is designed to provide rigidity and strength to the aluminum block. The deck areas are reinforced at the necessary areas and provide plenty of strength and support. The rear section of the four-cylinder didn't receive strengthening, which raises concern if the unit will be affected by the transmission. The emphasis on stress dispersion can be seen on the internals of the block. A smooth design (no rough edges) at the blow-by tunnels/ oil pan entrance and exit, and the connecting portion between the crank journal to the inside of the block shows that this engine is not affected by applied stress. Semi-Closed Deck Design For Longevity And Endurance The 4B11 is equipped with a semi-closed deck design with cast sleeves, which promotes longevity while cooling the engine significantly. The water jacket is designed so that it isn't affected by the bore structure, especially when installing the head bolts. This design makes changing the sleeves an easy task. Ventilation Openings That Lower Friction The 4B11 is fitted with many devices that eliminate friction in the assembly. The ventilation opening on the upper portion of the main journal is one of these. This was adopted from Porsche's race engines, which are known to fight pump loss. The blow-by gas is efficiently released and as a result lowers friction. Two-Section Oil Pan And Low-Friction Oil Pump The upper portion of the oil pan features ribs to keep the structure rigid. The oil pump is positioned at the lower end of the engine assembly, right below the upper oil pan to keep the suction of the pump at a minimal resistance. This setup is ideal during cornering and hard acceleration/deceleration. If the pan comes in contact with the ground, however, immediate oil pressure issues may come about. This gear type oil pump further minimizes friction than the conventional trochoid pumps seen on SR20s. A Newly Designed Engine With No Balance Shafts The pre-modern 4G63 was fitted with balance shafts, which were used to eliminate vibration. Many modified 4G63 engines had to have their balance shaft removed because it became a nuisance when tuning the engine. The new 4B11 doesn't come equipped with balance shafts. Overall, the engine itself is cleverly designed so that vibrations are nonexistent even without balance shafts. Baffle Plate That Lowers Blow-By Gas The oil pan is in two separated pieces and the upper aluminum oil pan is combined with a baffle plate. Six oil passes on each of the intake and exhaust sides on the cylinder head lead to exclusive oil return passages, where the oil drops down inside the oil pan. The amount of oil accumulated on the inner crankcase and crankshaft is decreased, which benefits by lowering the blow-by gases and improving oil pressure. On the 4G63, the level gauge tends to blow out when the engine is modified. The 4B11 already comes with a counter device that prevents the increased pressure of the blow-by gas from doing this type of damage. However, the area where the oil jets from the piston-cooling nozzle have the possibility of dropping straight below or at the wide clearance area between the crank weights and the baffle. Forged Mahle Pistons For High-Power Output Forged Mahle pistons with an 86mm bore and 23mm pin diameter are equipped in the 4B11. These pistons come with cooling channels with a different number of passages to the oil rings according to the intake and exhaust sides. The new piston pins were switched to a skirt-type, full-floating unit, replacing the ordinary forced pin oiler on the 4G63. Further inspection of the piston top reveals a rather shallow design suited for a forced-induction engine with an almost flat shape. Comparing it to an SR20DET, which is also 86mm, with an 8.5 compression configuration, the 4B has a slightly increased compression of 9.0. The top and secondary ring lands come thick in design, and along with the relatively high compression, this engine was made to withstand high horsepower. The piston pin and the rings weigh in at 546.2 grams. The 4G63 was engineered as a long stroke engine (85mm bore x 88mm stroke). Improved Conrod Design Once the 4G63 is heavily modified, the stock connecting rods cannot be used with full confidence. On the contrary, the 4B11 rods have beefier qualities with plenty of "meat" on the unit and great shoulder design. These rods also show indications of strength in design because of the lack of oil jet and bearing lubrication holes. Details of the connecting rods include M8 1.0 pitch-type rod bolts and the 4G63's dowel pin structure being replaced with a knock pin type. This part was designed with the bolt placement as center as possible. With the larger-sized crank pins, the bearing thickness was changed from 21mm to 17mm to contribute to less friction. The 4B11 rods are lighter, weighing in at 572.5 grams versus the 4G63 rods at 592 grams each. The slope ratio of the piston and connecting rod measures in at 3.34, advantageous criteria if the engine is going to be considered a 2.4-liter long stroke setup in the future. However, the torque-toyield connecting rod bolts that lack sufficient diameter may be an issue once the engine is modified to pump out more power. Compact Design Crankshaft The fully countered crankshaft has a 52mm main and crank pin area, which is skinnier than the 4G63's main pin but with thicker crank pins. This enables an overall strengthened crankshaft layout. The crank pick up sensor was moved to the rear area of the crankshaft. The flywheel position was relocated to the center of the entire assembly in order to create a more compact engine in terms of long-block height. The oil line that feeds lubrication to the crankshaft journals aren't the traditional "H" or "X" pattern, but a one of a kind design from Mitsubishi, presumably to supply plenty of oil to the bearings during high rpm. The concept of excessive oil supply related to extreme centrifugal force has been well balanced in this area. The crankshaft weighs in at 16.6kg. Rear Facing Exhaust Manifold Layout The reversed intake layout puts the exhaust side toward the rear of the vehicle. The manifold is designed for the traditional twin scroll type and is made from stainless steel, weighing in at 6.45kg. The same unit from the final version of the 4G63 weighs in at 6.8kg. The front pipe never extends a####### the oil pan, which minimizes oil temperature problems. Turbocharger Matched For 2.0- Liters On The Brink Of Completion The Evo IX was fitted with a TD05H166C-10.5T turbocharger, whereas the 4B11 comes equipped with a TD05H152G6-12T turbine. The new turbo has gone back to the traditional spinning rotation from the Evo IX's reversed scroll setup. Although the 4B11 turbo handles more volume, it also builds boost from the low rpm region with the lower trim impeller size. The impeller itself is made from aluminum and has a titanium aluminum turbine wheel that's good for 360 hp. The turbocharger relative to the 2.0-liter setup feels like a modified setup that's on its last tuning stages. As an option, an Inconel turbine wheel is available for higher loads. Big Capacity Outlet Pipe The outlet pipe is constructed in a bigger capacity to yield the combination of the exhaust gas coming from the turbo and the bypass gas coming from the swing valve. The 57mm outlet weighs 3 .3kg and seems like it's a high-quality aftermarket product. Electric Throttle- Enabled Surge Tank The 60mm throttle body diameter remains unchanged,however, the capacity of the surge tank was increased along with a design that emphasized in consistent and efficient air distribution to each cylinder. However, it's unfortunate that the intake manifold faces the front of the car, since the collector portion was designed to be positioned lower, like the SR20s seen in S13s. The electric throttle system should also raise problems for the aftermarket tuning industry. High-Resistance Injectors High-resistance Bosch injectors with 540cc/min were found in the 4B11 T/C engine. The outer casing of the injector looks identical to that from the VQ35DE, but shows a variance with its extended nozzle. These injectors don't protrude inside the ports for the specific reason of decreasing intake air resistance. 4B11 In Comparison And Final Engine Analysis The overall synopsis of the disassembly of the 4B11 T/C revealed the obvious. The new Lancer Evolution 4B is a completely different engine from the 4G63. It was interesting to reveal after #######-referencing our data that we found many dimensions to be similar to the SR20 engine. Originally, the vertically laid out 4G63 is an old design, which was improved gradually until its final model equipped in the Evo IX. The final 4G63 pushed out 280 hp/6,500 rpm and 41.5kg-m/3,000 rpm of torque. The 4B11 was designed with this final model in mind, and on top of that more performance and numerous efficiency features were added to an engine that was designed to maintain low-emission characteristics. The 4B11 T/C pushes 280 ps/6,500 rpm (Japan spec) as well, and an increased torque output of 43.0kg-m/3,500 rpm, which still complies with the recent Japanese emissions standards. Although the power output regulations were abolished (Japan), the vehicle was kept at 280 ps but with the added performance aspects over the Evo IX. Upon completing the reverse engineering process of the engine, we came to the conclusion that the overall design of the 4B11 is a sign of the times that follows a new trend of modern conventional engines we see today. At this time, the fact that the engine is comprised of an aluminum block may scare off many who have become accustomed to the 4G63 cast-iron block. Many fear that since this is an aluminum engine it's prone to such problems as engine knock during tuning, burnt pistons, boring of the cylinders (ignoring the sleeve thickness) and re-sleeving. However, we've found the 4B11 to be a good engine. With Tomei Powered's years of experience and extensive knowledge gained with the 4G63, SR20DET and EJ20 engines, we're confident to say that the 4B11 is definitely an engine that can be modified for increased performance. To what level of modifications is too early to say but stay tuned as Tomei Powered will use this detailed information gathered from our engineers and build new and exciting products for the 4B11. |

|

|

|

26.4.2009, 18:36 26.4.2009, 18:36

Сообщение

#10

|

|

Зарегистрированный пользователь  Группа: Член клуба Сообщений: 1090 Регистрация: 6.10.2008 Из: Москва |

Короче вывод такой - покупайте наши тюнячки.

4б11 типа экологичней бла бла бла, но мы считаем что ее всетаки можно тюнить... :) |

|

|

|

26.4.2009, 18:57 26.4.2009, 18:57

Сообщение

#11

|

|

Зарегистрированный пользователь  Группа: Пользователь Сообщений: 1715 Регистрация: 22.6.2006 |

|

|

|

|

26.4.2009, 19:04 26.4.2009, 19:04

Сообщение

#12

|

|

Зарегистрированный пользователь  Группа: Член клуба Сообщений: 1090 Регистрация: 6.10.2008 Из: Москва |

вывод: 4B11 изначально более продуманный двигатель, разработанный с учетом недостатков предыдущего поколения :))) Как бэ да, но... Он сделан под новый японские экологические стандарты бла бла бла... :) Короче кидалово все это :) Они если и думали, то только над экологией :) |

|

|

|

28.4.2009, 9:09 28.4.2009, 9:09

Сообщение

#13

|

|

Зарегистрированный пользователь  Группа: Пользователь Сообщений: 1715 Регистрация: 22.6.2006 |

Как бэ да, но... Он сделан под новый японские экологические стандарты бла бла бла... :) Короче кидалово все это :) Они если и думали, то только над экологией :) у не совсем. не помню как в 4G63, но в новом движке уже изначально кованные поршня мале стоят и прокладка блока головки металлическая, ламинированная стоит. ну и еще по мелочи много чего поменяли, что говорит о потенциале. |

|

|

|

|

| Текстовая версия | Сейчас: 27.4.2024, 16:37 |